When welding certain base metals and under specific service conditions, preheating and/or post-weld heat treatment (PWHT) may be required. These thermal treatments ensure weld integrity, minimize the risk of cracking, and enhance the service life of welded components. Heat treatments, however, are not without cost—they demand extra equipment, time, and handling. For this reason, their use must always be carefully considered. In some cases, such as with heavy sections of low-alloy steels, heat treatment is mandatory. In others, it is applied as a precautionary measure to prevent early service failure.

This article explores the most important aspects of preheating and post-weld heat treatments, why they are needed, how they are performed, and what the welding inspector should always be aware of when overseeing these procedures.

I. Preheating

.jpg)

1) Definition and Purpose

The American Welding Society (AWS) defines preheat as “the heat applied to the base metal or substrate to attain and maintain preheat temperature.” The preheat temperature is “the temperature of the base metal in the volume surrounding the point of welding immediately before welding is started. In a multipass weld, it is also the temperature immediately before the second and subsequent passes are started.”

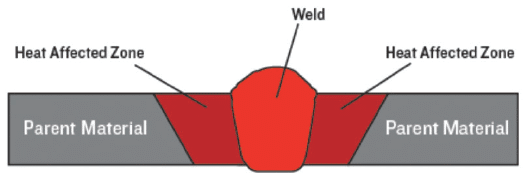

In simple terms, preheating raises the temperature of the base material around the weld zone before welding begins and maintains it between weld passes. This process reduces cooling rates, controls metallurgical changes, and minimizes the risk of hydrogen cracking.

2) Why Preheating is Required?

Preheating serves multiple critical purposes:

Driving off Moisture: Preheating removes surface moisture and contaminants that could introduce hydrogen into the weld, reducing the risk of porosity and hydrogen-induced cracking. Even mild preheat (just above 100°C) can eliminate residual moisture.

Reducing the Thermal Gradient: Arc welding produces localized, intense heat. Without preheating, the steep temperature difference between molten weld metal and the cool base metal can lead to rapid cooling, high residual stresses, and distortion. Preheat reduces this gradient, mitigating these issues.

Preventing Hard and Brittle Microstructures: Certain steels, especially high-carbon and low-alloy steels, are prone to forming martensite during rapid cooling. Martensite is hard, brittle, and highly crack-sensitive. Preheating slows the cooling rate, encouraging the formation of softer, more ductile structures such as bainite or ferrite-pearlite.

Enhancing Weldability of Alloys:

Nickel alloys: Preheat reduces risks associated with constitutional liquation and carbide precipitation.

Aluminum alloys (2xxx, 6xxx, 7xxx series): Preheat and interpass temperatures must be carefully controlled to prevent over-aging of the heat-affected zone (HAZ).

Chromium-molybdenum steels: Require careful preheat and interpass temperature management to balance toughness and crack resistance.

3) Factors Affecting Preheat Requirements

The required preheat depends on several factors:

Base Metal Composition – Steels with higher carbon or alloy content generally require higher preheat to reduce hardenability and cracking risk.

Material Thickness – Thicker sections cool faster and therefore require greater preheat.

Hydrogen Content of Welding Process – Processes with higher diffusible hydrogen levels (e.g., shielded metal arc welding) may require higher preheat.

Joint Restraint – Highly restrained joints are more susceptible to cracking, requiring greater preheat.

Service Conditions – Applications exposed to fatigue, impact loading, or harsh environments demand tighter control.

4) How to Perform Preheating?

Preheating can be achieved in a variety of ways:

Gas burners and torches: Often used for large plates and structures. Care must be taken to avoid localized overheating.

Oxy-gas flames: A common method for thick or high-strength steels.

Electric heating blankets: Provide controlled and uniform heating, particularly in field applications.

Induction heating: Fast, uniform, and precise—especially suited for controlled environments.

Furnaces: Used when an entire assembly or component needs to be uniformly heated.

For best results, preheating must be uniform around the joint area. Uneven heating can cause higher residual stresses, distortion, or undesirable metallurgical transformations.

When heating from one side, temperature should be measured on the opposite side to ensure through-thickness uniformity.

If heating and temperature measurement are both carried out on the same side, care must be taken to ensure that the entire material thickness is uniformly heated, not just the surface.

5) Interpass Temperature Control

In addition to preheat, interpass temperature is often specified. This refers to the minimum or maximum temperature that must be maintained between weld passes.

If the interpass temperature is too low, rapid cooling may occur, increasing the risk of martensite formation and cracking.

If it is too high, excessive grain growth, loss of mechanical properties, or hot cracking may result.

Welding procedure specifications (WPS) define these limits. The welding inspector must ensure that the weld area does not exceed the maximum interpass temperature and, if necessary, allow the weldment to cool before continuing.

6) Control and Monitoring of Preheat

For critical applications, preheat must be precisely controlled. This involves:

Controllable heating systems that regulate power automatically.

Thermocouples placed at multiple locations around the weld to measure true material temperature, not just surface conditions.

Recording devices to document compliance with the WPS and code requirements.

These measures ensure that the preheat temperature remains within specified tolerances, even in complex weldments.

II. Post-Weld Heat Treatment (PWHT)

Once welding is complete, the welded component may require post-weld heat treatment to improve mechanical properties, reduce stresses, or restore material characteristics altered by welding.

PWHT is not a single process—it encompasses several types of thermal treatments, each with distinct objectives.

1) Types and Purposes of PWHT

a) Stress Relieving

Residual stresses are inevitable in welded joints due to uneven heating and cooling. High residual stresses can:

Lead to brittle fracture.

Increase susceptibility to stress-corrosion cracking.

Cause distortion during machining or service.

Stress relief involves heating the weldment to a moderate temperature (commonly 550–650°C for steels), holding it long enough to allow stress relaxation, and then cooling it slowly.

b) Achieving Suitable Metallurgical Structures

Certain alloy steels require tempering after welding to achieve desired microstructures. For example:

Quenched and tempered steels regain toughness and ductility after tempering.

Without tempering, the HAZ may contain brittle, crack-sensitive microstructures.

c) Normalizing

For steels with coarse grain structures—often produced by processes like electroslag welding—normalizing may be required. The weldment is heated to just above the upper critical temperature (around 900°C), held, and then air-cooled. This refines the grain structure, relieves stresses, and reduces hardness.

d) Restoring Properties of Precipitation-Hardened Alloys

Heat-treatable aluminum alloys and precipitation-hardened steels may lose their original mechanical properties during welding. PWHT (solution treatment followed by artificial aging, or aging alone) restores strength, toughness, and corrosion resistance.

2) Factors Influencing PWHT Decisions

Material Type: Low-alloy steels, stainless steels, nickel alloys, and aluminum alloys all respond differently.

Component Thickness: Thicker sections accumulate more residual stress and benefit from PWHT.

Service Requirements: Pressure vessels, pipelines, and critical structural components often mandate PWHT under code.

Applicable Standards: Codes such as ASME, AWS, and ISO specify when PWHT is mandatory.

3) Risks of Improper PWHT

Improperly applied PWHT can be harmful:

Overheating can cause grain coarsening, reducing toughness.

Excessive soaking can reduce strength.

Rapid cooling after PWHT may reintroduce residual stresses.

The welding inspector must ensure procedures are followed precisely, using calibrated equipment and verified temperature controls.

III. The Role of the Welding Inspector

The welding inspector plays a critical role in both preheating and PWHT:

Verifying that preheat temperatures meet the WPS before welding begins.

Ensuring that interpass temperatures remain within limits throughout multipass welding.

Monitoring PWHT cycles, including ramp-up, soak, and controlled cooling phases.

Confirming compliance with applicable codes and specifications.

Ensuring documentation and traceability for all heat treatments performed.

Failure to properly apply or monitor heat treatments can compromise weld quality, reduce component service life, and in critical cases, lead to catastrophic failure.

Conclusion

Preheating and post-weld heat treatments are not optional conveniences—they are essential metallurgical tools that directly influence weld quality, safety, and durability. While they add cost, time, and complexity, the benefits far outweigh the risks of neglecting them.

The inspector must understand the reasoning, procedures, and implications of both preheating and PWHT. With careful planning, precise control, and strict adherence to specifications, these treatments ensure weldments perform reliably under demanding service conditions.

Related articles:

1. Welding Hot Cracking, Reheat Cracking, Cold Cracking & Tearing

2. How To Prep Metal For Welding: A Complete Guide

3. How To Clean Stainless Steel Welds After Welding? [Easiest Way]

4. What to Do If the Product's Weld Joints Still Leak after Welding?

5. Why Does Stainless Steel Rust After Welding?

.jpg)